Product Characteristics

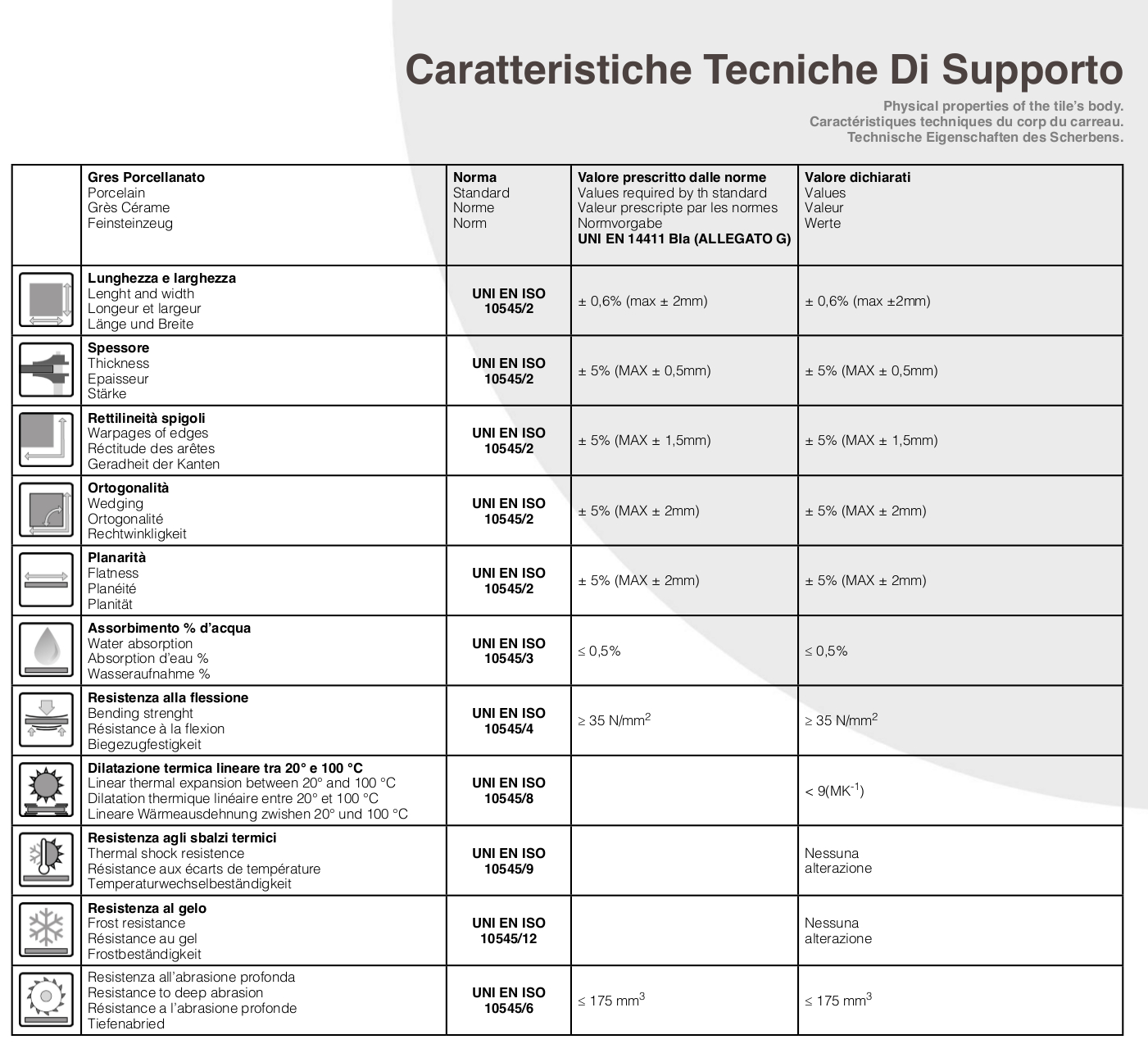

Technical Characteristics

It is the measure of the quantity of water absorbed by the tile completely immersed in water, brought to boiling for 2 hours and cooled naturally for the next 24 hours. Since this absorption takes place through the pores of the material that are in communication with the external surface, it therefore provides an immediate indication of the structure of the material. Porosity less than 0.1% is synonymous with great compactness, very high mechanical strength, easy cleanability and absolute frost resistance of the material.

It corresponds to the maximum voltage that a specimen of the material itself, subjected to increasing stress and with defined procedures, can withstand before breaking. The higher the compactness and the lower the water absorption, the greater the value required to reach the tile break. It is important to underline that the breaking load of the single tile, measured according to EN ISO 10545/4 standard is generally much lower than the actual load capacity of the same tile in operation, once inserted in the floor. It can be demonstrated, through calculations and mathematical models, that the load capacity of the laid tile is even more than a few dozen times, with respect to the load that causes the breakage of the single tile released from the plane during the bending strength test in the laboratory of laying. This conclusion is also intuitive, taking into account the collaboration with the resistance to mechanical stresses, which the tile receives from the layers (supporting structure) permanently connected to it.

The shown values indicate the class to which the individual items belong according to the UNI EN ISO 10545/6 standard, which determines the abrasion resistance of the surface exclusively according to the PEI method. The classification includes five classes, ranging from V, the most resistant, to I, the least resistant.

The chemical attack for enamelled surfaces is performed with normalized solutions of chloridic acid and potassium hydroxide for 4 days; pool additives, citric acid and ammonium chloride for 24 hours. The pencil test is then performed. At the end of the test the classification includes 3 classes of which the GA indicates the absolute impregnability, and the GB and GC classes indicate increasingly evident attackability. The chemical attack for unglazed products is carried out by immersion and for 12 days in standardized solutions of: household chemicals, pool additives; solutions in hydrochloric acid, lactic acid, citric acid and potassium hydroxide. Also in this case the classification foresees 3 classes of which the UA indicates the absolute impregnability, and the classes UB and UC indicate increasingly evident attackability.

The test method involves the application of staining substances (chromium oxide, iron oxide, iodine dye, olive oil) and subsequent cleaning in sequence with gradually more effective normalized detergents (hot water at 55 ° C, non-abrasive detergent, detergent with abrasive, solvents). Once the test has been carried out, the classification includes five classes, ranging from 5, the easiest to clean, to 2, the most difficult. Class 1 indicates that the stain has not been removed.

Temperature fluctuations are the sudden temperature variations that can occur on the tiles covering floors and walls by contact, either causal or intentional, with hot or cold bodies (for example, due to the fall of a boiling liquid, for cleaning with steam machines, or in the case of external floors or walls, due to sudden weather changes, etc.). Resistance to thermal shocks is the characteristic for which the tiles are able to withstand such events without being damaged. The procedure (specified in the standard EN ISO 10545/9) consists of having the test tiles undergo 10 thermal cycles between 15 ° C and 145 ° C. After 5 minutes at low temperature, the samples must be placed in an oven at 145 ° C for about 20 minutes and then brought back to low temperature conditions. At the end of the 10 foreseen cycles, the samples are examined visually to identify any defects.

It is the parameter used to characterize the slipperiness of a surface. The higher the friction coefficient, the lower the slipperiness. In the case of floors, it is clear that slipperiness is linked to the safety of walking, especially for tiles intended for floors in particular public and industrial outdoor areas. As far as the nature of the surfaces is concerned, it is logical that the friction coefficient is lower the more the surface is smooth to become higher in the presence of rough surfaces. It should be noted that these latter surfaces that make the conditions of safety in relation to the prevention of slipping optimal are such as to make cleaning operations more difficult instead. It is an important fact, which must be taken into account when choosing the floor material. Currently the most used methods for determining the degree of slipperiness in flooring are substantially 3:

- English method BCR tortus

- German method DIN 51130 (with footwear); DIN 51097 (barefoot)

- American method ASTM C 1028

The Italian legislation recognizes the BCR tortus method to assess the slipperiness of floors subjected to the safety constraints imposed by D.M. N ° 236 of 14.06.89 concerning the removal of architectural barriers for disabled people.

BCR tortus: English derivation method which measures the coefficient of friction using a portable mobile device; equipped with an electric motor it moves at a constant speed on the surface of the tiles to be tested. The friction coefficient that is exerted between the tile and the sliding contact element is determined, covered with standardized leather and rubber padding, in dry and then wet conditions. This method can be used both in the laboratory and in the field. The results are evaluated according to the following classification:

| Less than | 0,19 | Dangerous slipperiness |

| From | 0,20 to 0,39 | Excessive slipperiness |

| From | 0,40 to 0,74 | Satisfactory friction |

| Greater than | 0,75 | Excellent friction |

DIN 51130 / DIN 51097: The method is that of the inclined plane, where a person walks back and forth on a platform covered with ceramic tiles. The inclination of the test area is increased with constant speed up to the point where the person shows uncertainty in walking (ie he starts to slip). At this point the test is interrupted and the inclination angle of the platform is recorded, which corresponds to a classification (R for dry floors, A for wet floors). The test is carried out by wearing standardized footwear and applying oil with standard characteristics in one case, and in the other with bare feet on ceramic floors in the presence of water. This test can only be performed in the laboratory and not in the field. The results are evaluated according to the diagram below:

| DIN 51130 (shoes+oil) | DIN 51097 (bare feet+water) | ||

| from 6° up to 10° | R 9 | < 12° | 0 |

| over 10° up to 19° | R 10 | from 12° to 17,9° | A |

| over 19° up to 27° | R 11 | from 18° to 23,9° | B |

| over 27° up to 35° | R 12 | over 23,9° | C |

| over 35° | R 13 | ||

| R 9 | Entrance areas and stairs with access from the outside; restaurants and canteens; shops, clinics, hospitals, schools. |

| R 10 | Shared bathrooms and showers; small kitchens for catering establishments; underground garages. |

| R 11 | Environments for the production of foodstuffs; medium-sized kitchens for catering establishments; with volumes below 100 seats; work environments with strong presence of water and mud; laundries, laboratories, hangars. |

| R 12 | Environments for the production of food rich in fats, such as: cheeses, butter, oils, ice creams, cold cuts: large kitchens for catering establishments with volumes exceeding 100 seats, industrial wards with the use of slippery substances: paints, muds, liquid glues ; car parking lots. |

| R 13 | Environments with large amounts of fat; processing of meat, fish and vegetables; tanneries. For more precise and detailed information, see the information brochure published by the German technical committee for accident prevention and occupational health: Alte Heerstrasse 111, 53754, ST. AUGUSTIN Technical Committee “building structure” floors order number: ZH 1/571 edition July 93. |

ASTM C 1028: This derivation method from the United States measures the static friction coefficient by means of a dynamometer, which determines the force necessary to start the movement between the sliding element (coated in standardized rubber) and the surface of the tile, both in dry and wet conditions. Also this method can be carried out both in the laboratory and in the field. The result is evaluated according to the following classification:

| Less than | 0,50 | Insufficien friction |

| From | 0,50 to 0,60 | Sufficient friction |

| Over | 0,60 | Excellent friction |

Preset size of a tile and to which the real size must approach within tolerance limits.

Actual size of the content in the box, clearly specified on the same as well as in the sales documents.